VTP – Variable Twin Planet Functional description

VTP (Variable Twin Planet)

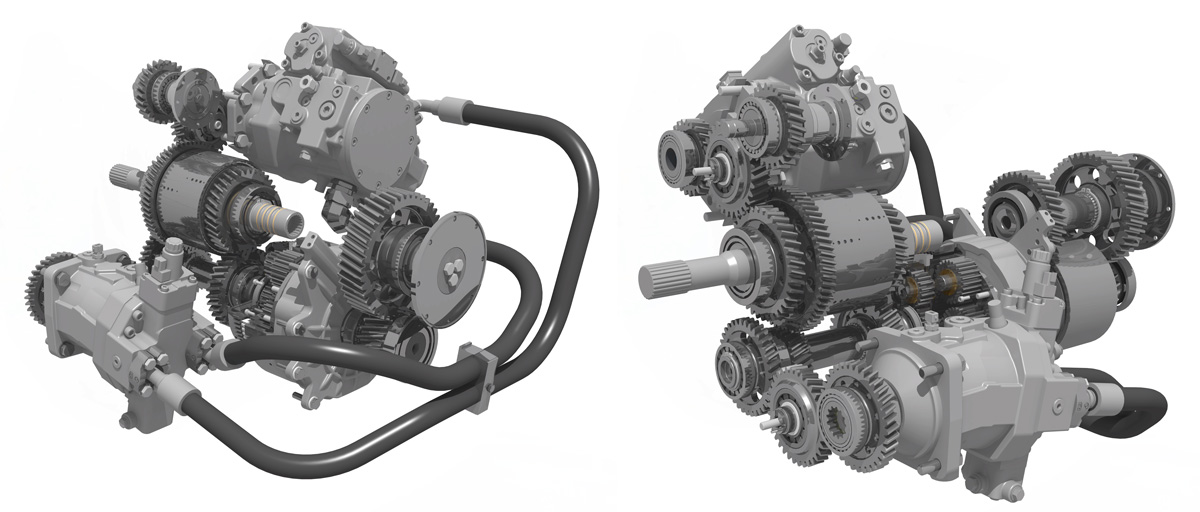

The patented VTP stepless gearbox was developed with the aim of achieving competitive manufacturing costs even for small quantities, optimum functionality, the best possible efficiency, easy adaptability to customer-specific installation conditions, robustness and reliability.

The application segments range from agricultural machinery (tractors, sprayers), municipal and forestry vehicles to off-road vehicles for extreme applications. The following statement applies: “The more difficult the operating conditions and the higher the efficiency requirements, the more advantages the VTP continuously variable transmission offers”. Over the past few years, continuously variable transmissions and complete tractor drive units have been developed on the basis of the VTP functional principle for input powers from 80 to 320 kW.

The VTP transmissions are equipped with hydrostatic variators as standard; hybrid transmissions with electric variators are currently being tested.

VTP system – Variable Twin Planet

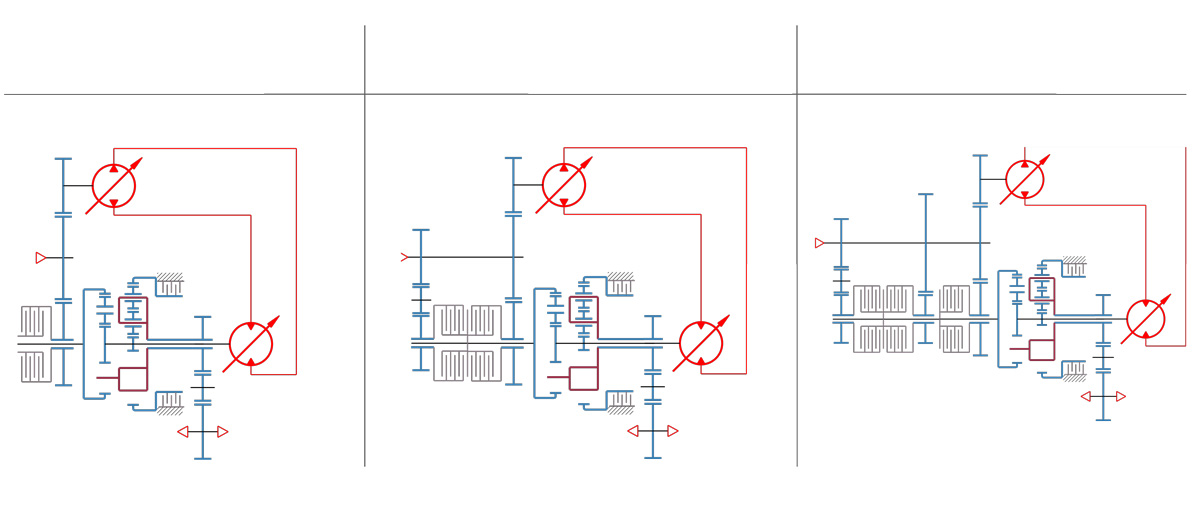

How it works: The Variable Twin Planet (VTP) defines a new range of continuously variable transmissions (IVT) that operate on the principle of hydrostatic-mechanical or electro-mechanical power split. To achieve high gradeability and high tractive forces with appropriate variator sizes, the transmission can be configured with one, two or three mechanical gears that are shifted via powershift clutches.

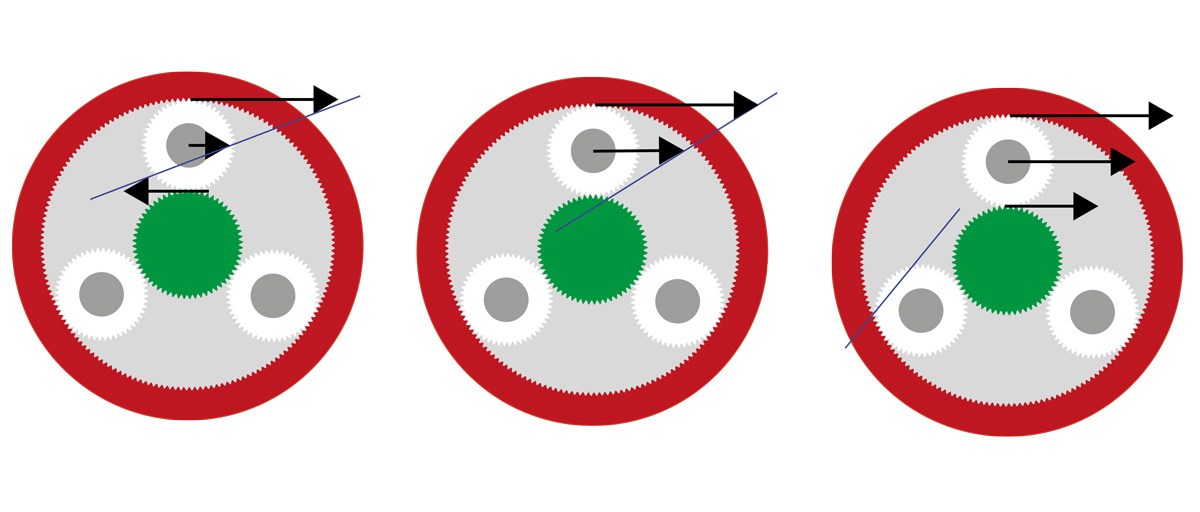

Ring gear: Incoming mechanical power

Sun gear: Driven by variator or hydrostatic or electric power

Carrier: Variable output speed

System and function description:

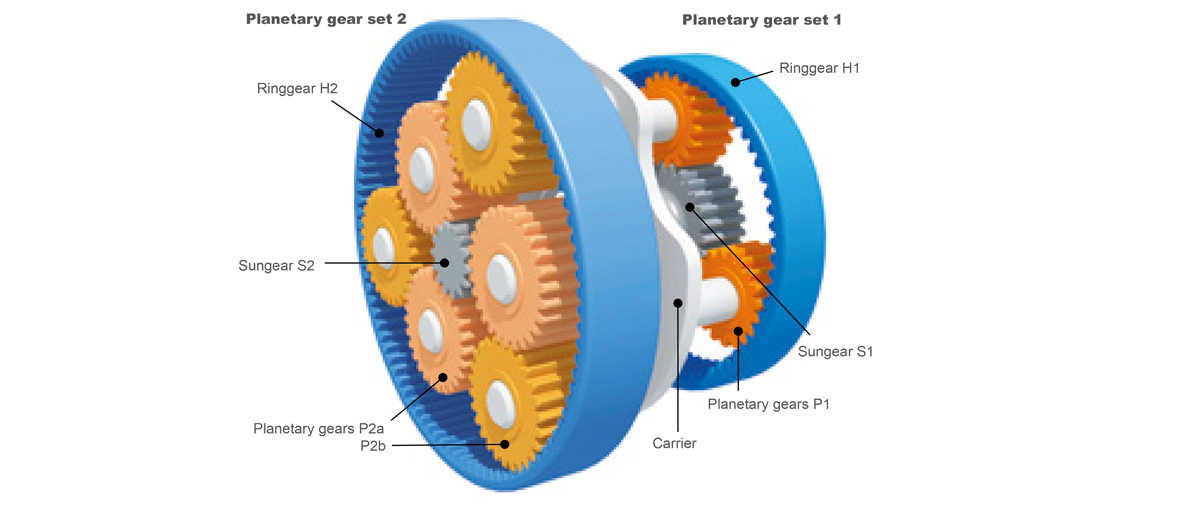

The main element of the innovative VTP continuously variable transmission is a twin planetary gear set at the transmission output. One of the two planetary gear sets is a reverse planetary gear and is only active at low speeds in pure variator mode (gear set 2), while the superimposition of mechanical and variator power takes place in planetary system 1. The selected arrangement and the transmission ratios in the two planetary gearboxes offer excellent climbing ability with small variator units and a large gearbox span with low mechanical effort. Variators such as compact hydraulic units in a back-to-back arrangement, separate hydraulic pumps and hydraulic motors in a closed circuit or electric variators can be used. At low speeds, the vehicle is only driven by the hydrostatic branch. The connection of the ring gear H2 with the housing in the planetary gear set 2 transmits the power from the hydraulic motor via the sun gear S2 and the planet carrier to the drive wheels (see illustration on page 6). The gear components in the mechanical power path do not transmit any load in this operating range. Their speeds at the drive end are defined by their coupling in the planetary gearbox 1 and on the input side by the coupling to the gearbox input shaft. The planetary gear set 2 has a high transmission ratio in order to achieve high tractive forces with small hydrostatic units.

The rotary motion of the sun gears S1 and S2 or the planet carrier forces a speed at the ring gear H1, which leads to synchronous speeds if the speed of the sun gears at the clutches K1 in forward gear or at the clutch KR in reverse gear is high enough. When the synchronization speed is reached, the system switches from the hydrostatic drive to the continuous power branch without interrupting the output torque and the corresponding tractive force. Shifting takes place by overlapping the closing of the respective clutch and the subsequent opening of the ring gear brake. The clutches and brakes are multi-disc models.

After shifting, the mechanical drive is transmitted via the ring gear H1, which is coupled to the transmission input shaft and rotates at a constant speed. A continuous change in the speed of the hydrostatic branch continuously adjusts the overall transmission ratio.

Immediately after shifting into the power split range, the sun gear in planetary system 1 rotates in the opposite direction to the ring gear, thereby reducing the speed of the planet carrier. In this operating range, the transmission works in reverse mode, which means that the hydraulic motor works as a pump and feeds back into the mechanical branch via the hydrostatic circuit. By changing the swivel angle of the hydraulic pump thrust plate, the speed of the hydraulic motor is adjusted from maximum speed against the direction of the ring gear via the angle zero to the maximum speed in the same direction as the ring gear H1. At a swivel angle of zero, the gearbox operates with maximum efficiency, as the entire drive power is transmitted purely mechanically. The hydraulic motor only has to compensate for the power loss in order to support the torque of the sun gear S1 at zero speed. With further adjustment of the thrust washer, the speed of the sun gear S1 increases in the same direction as the ring gear H1 until the maximum travel speed is reached in the first power split range. The change from the first to the second power split range takes place by means of a power shift, with the variator unit compensating for the step.

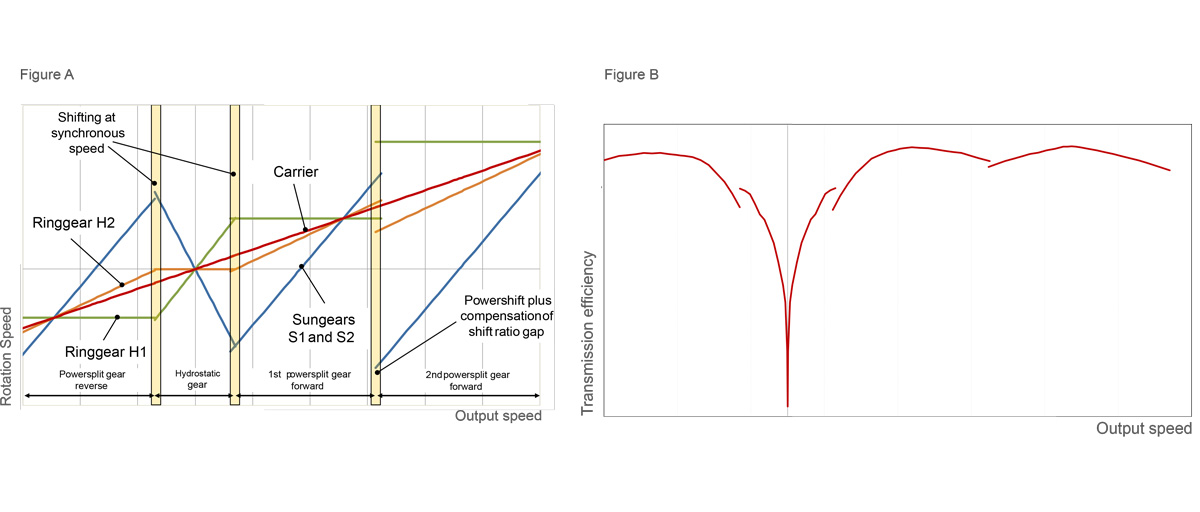

Figure A shows the ratio of speeds in a VTP transmission with a purely hydrostatic driving range at low speeds as well as two power split ranges for forward driving and one power split range for reverse driving.

Figure B shows the efficiency curve as a function of the driving speed at a constant input speed. The characteristic “camel humps” in the middle of the power split ranges, where the entire drive power is transmitted purely mechanically and the gearbox offers the best efficiency, are striking.

Significant advantages:

- Very good efficiency values in the main operating ranges due to the design with double planetary system and small hydrostatic units

- Permanent torque flow between motor and drive wheels.

- The motor is operated in the optimum power range.

- Full tractive force even at low engine speed

Maximum ride comfort and safe operation:

- Smooth, uninterrupted start-up

- Continuous flow of force during acceleration or deceleration

- Fully automated drive train

- Cruise control is integrated

- No stalling of the engine

- Full utilization of engine braking power during deceleration through targeted adaptation of the gear ratio