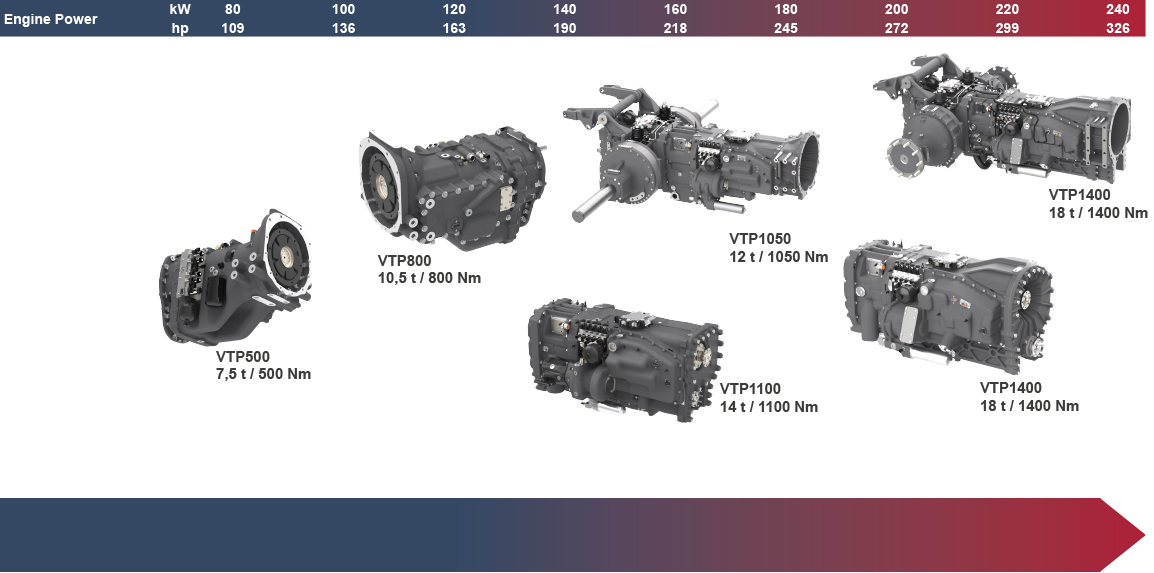

Continuously variable transmission for tractors and forestry machines

VTP 500

7.5 t/500 Nm

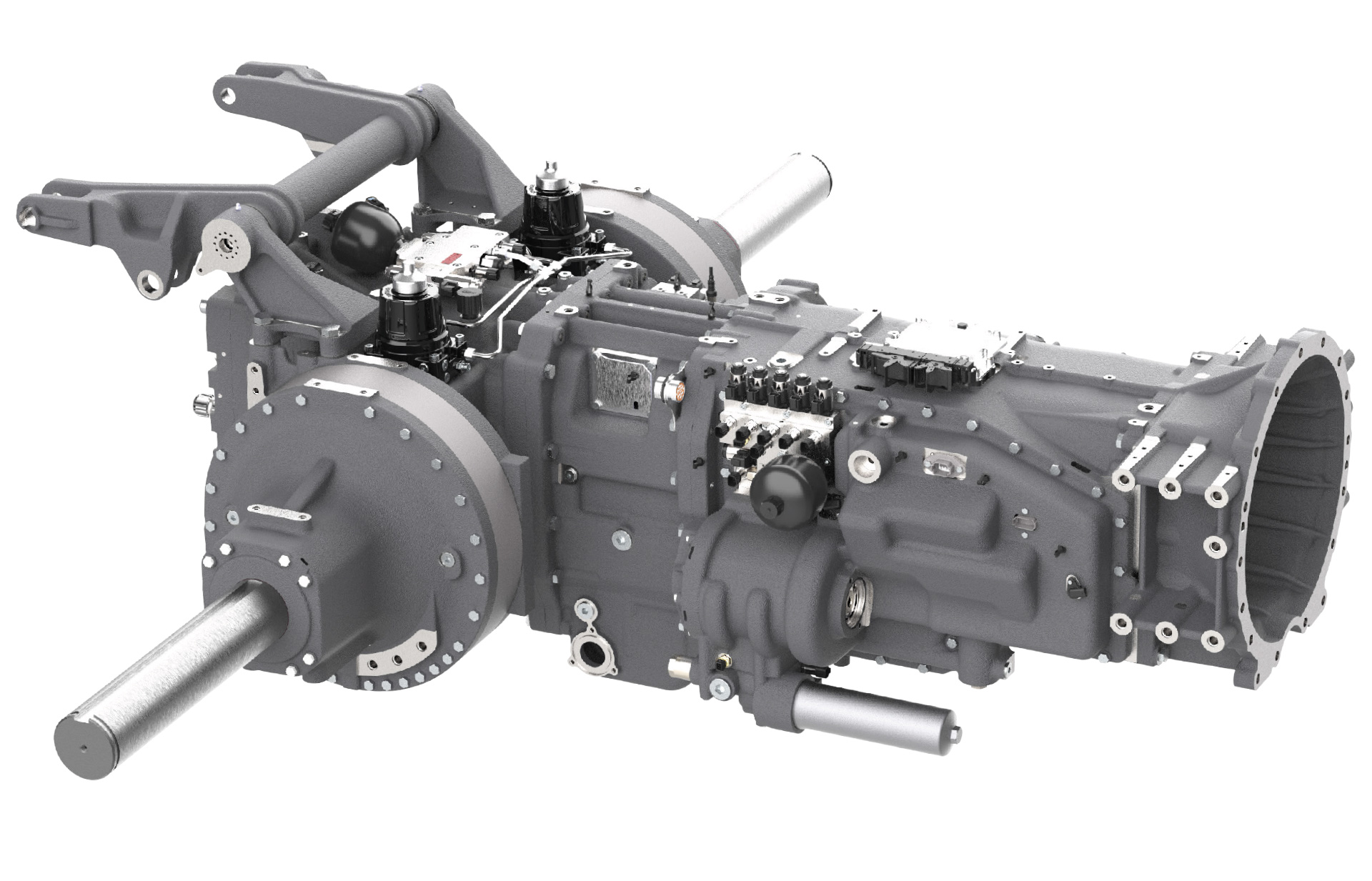

VTP800

10.5 t/800 Nm

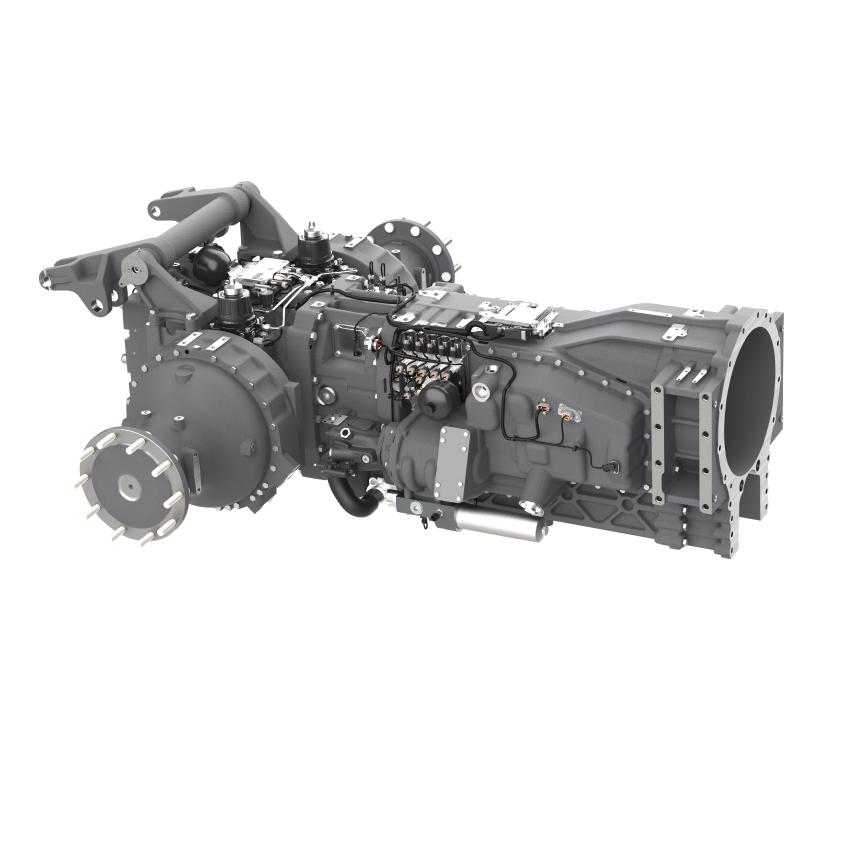

VTP1100

14 t/1100 Nm

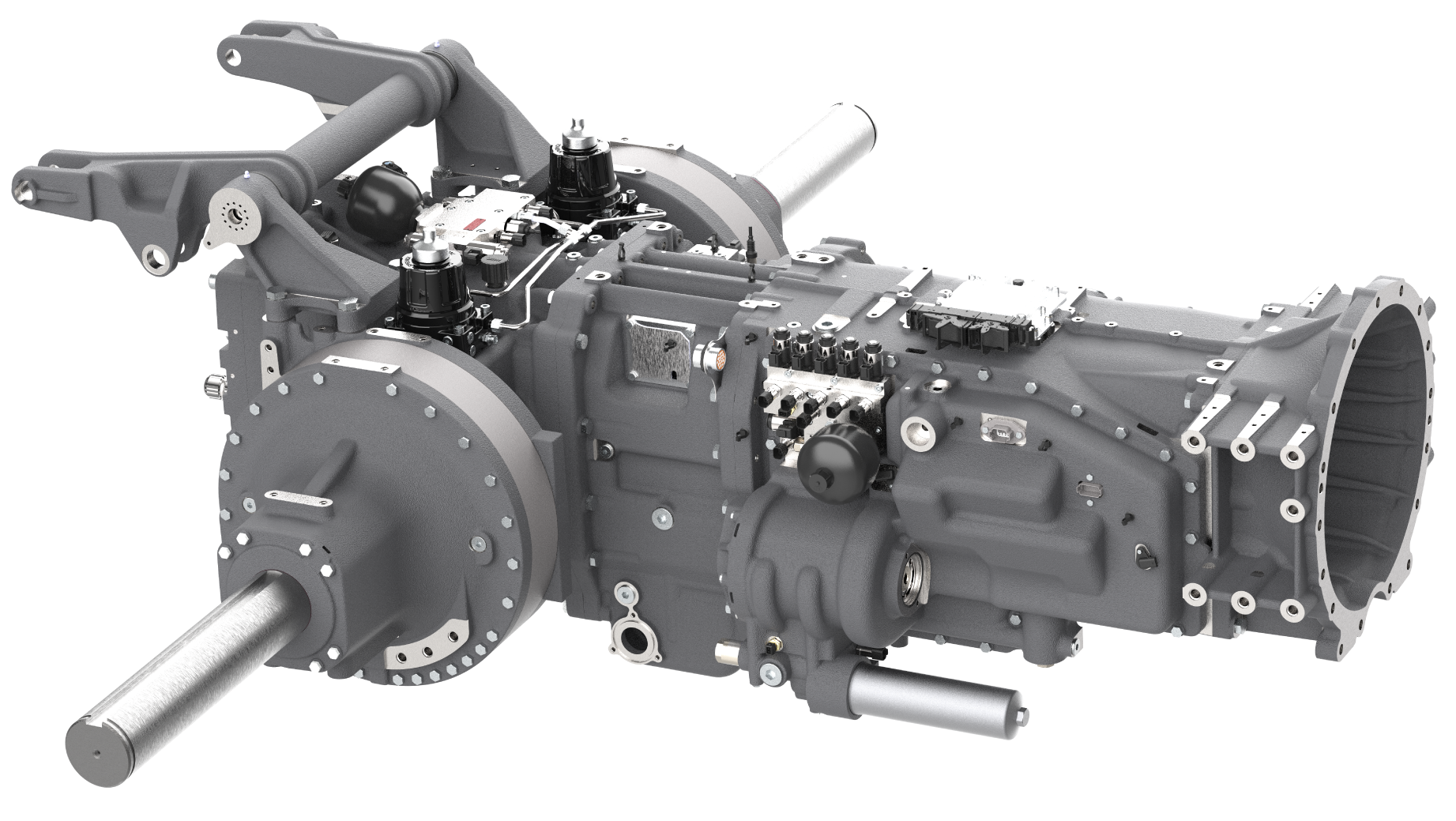

VTP1400

18 t/1400 Nm

Details – Gearbox configuration – Performance data

The VTP modular transmission system developed by VDS represents an optimal configuration of mechanical components and hydrostatic variators. This system is based on the principle of hydrostatic-mechanical power splitting and offers up to three superposition ranges (1R, and 2V), it can be equipped with/without high-low group, depending on the version.

The heart of the VTP transmission system, consisting of two drive trains (mechanical and hydrostatic), is a double planetary set at the transmission output (summing planetary module). In purely hydrostatic operation, the reversing planetary set is only active at low speeds, while the second planetary set superimposes mechanically and hydrostatically transmitted power. This results in high tractive force potential and a large gear spread, while at the same time minimizing mechanical effort.

The VTP transmission system is already used in almost all “off-highway” vehicle segments. Thanks to its modular design and availability in various sizes, which can be combined with different variators, the VTP system offers the flexibility to provide cost-efficient solutions even for small quantities. In this context, the VTP gearbox system is the ideal solution and enables the integration of all components required for stepless gearbox adjustment in a “basic module” and in any size.

| VTP500 | 1 powersplit gear rev – hydrostatic rev/fwd – 2 powersplit gears fwd |

| Rated input power | 100 kW (135 hp) |

| Rated input speed | 2300 rpm |

| Max input torque | 500 Nm |

| Max output torque | 1550 Nm |

| Transmission ratios | rev -0.82 to ∞ / fwd ∞ to 0.43 |

| Control unit | Bosch RC30 / RC40 |

| Electronic interface | CAN-J1939 |

| GVW | 7 t |

| VTP800 | 1 powersplit gear rev – hydrostatic rev/fwd – 2 powersplit gears fwd high-low range gear |

| Rated input power | 120 kW (170 hp) |

| Rated input speed | 2200 rpm |

| Max input torque | 800 Nm |

| Max output torque | 3200 Nm |

| Transmission ratios | rev -0.84 to -∞ / fwd ∞ to 0.48 |

| Control unit | Bosch RC30 / RC40 |

| Electronic interface | CAN-J1939 |

| GVW | 10,5 t |

| VTP1100 | 1 powersplit gear rev – hydrostatic rev/fwd – 2 powersplit gears fwd high-low range gear |

| Rated input power | 180 kW (240 hp) |

| Rated input speed | 2100 rpm |

| Max input torque | 1100 Nm |

| Max output torque | 4450 Nm |

| Transmission ratios | rev -0.75 to ∞ / fwd ∞ to 0.42 |

| Control unit | Bosch RC30 / RC40 |

| Electronic interface | CAN-J1939 |

| GVW | 14 t |

| VTP1400 | 1 powersplit gear rev – hydrostatic rev/fwd – 2 powersplit gears fwd high-low range gear |

| Rated input power | 250 kW (340 hp) |

| Rated input speed | 2100 rpm |

| Max input torque | 1400 Nm |

| Max output torque | 3800 Nm |

| Transmission ratios | rev -0.55 to ∞ / fwd ∞ to 0.31 |

| Control unit | Bosch RC30 / RC40 |

| Electronic interface | CAN-J1939 |

| GVW | 18 t |

Engines for tractors

Details – Engine configuration – Performance data

| VTP1050 | 1 powersplit gear rev – hydrostatic rev / fwd – 2 powersplit gears fwd, high-low range gear |

| Rated input power | 160 kW (220 hp) |

| Rated input speed | 2200 rpm |

| Max input torque | 1050 Nm |

| Max axle torque | 97 kNm |

| Wheel speed -/+ | -116 rpm / +151 rpm |

| Static tire radius (SRI) | 887 mm |

| Control unit | Bosch RC30 / RC40 |

| Electronic interface | CAN-J1939 |

| Differential lock | friction disks |

| PTO speeds | 540E / 1000 / 1000E 540 / 540E / 1000 |

| Lift capacity | 11 t |

| GVW | 12 t |

| VTP1400 | 1 powersplit gear rev – hydrostatic rev / fwd – 2 powersplit gears fwd, high-low range gear |

| Rated input power | 250 kW (340 hp) |

| Rated input speed | 2100 Nm |

| Max input torque | 1400 Nm |

| Max axle torque | 150 kNm |

| Wheel speed -/+ | -90 rpm / +170 rpm |

| Static tire radius (SRI) | 1025 mm |

| Control unit | Bosch RC30 / RC40 |

| Electronic interface | CAN-J1939 |

| Differential lock | friction disks |

| PTO speeds | 540E / 1000 / 1000E 540 / 540E / 1000 |

| Lift capacity | 12,5 t |

| GVW | 18 t |